Blog

Meltio Engine integration with Robot

Meltio Engine integration with Robot

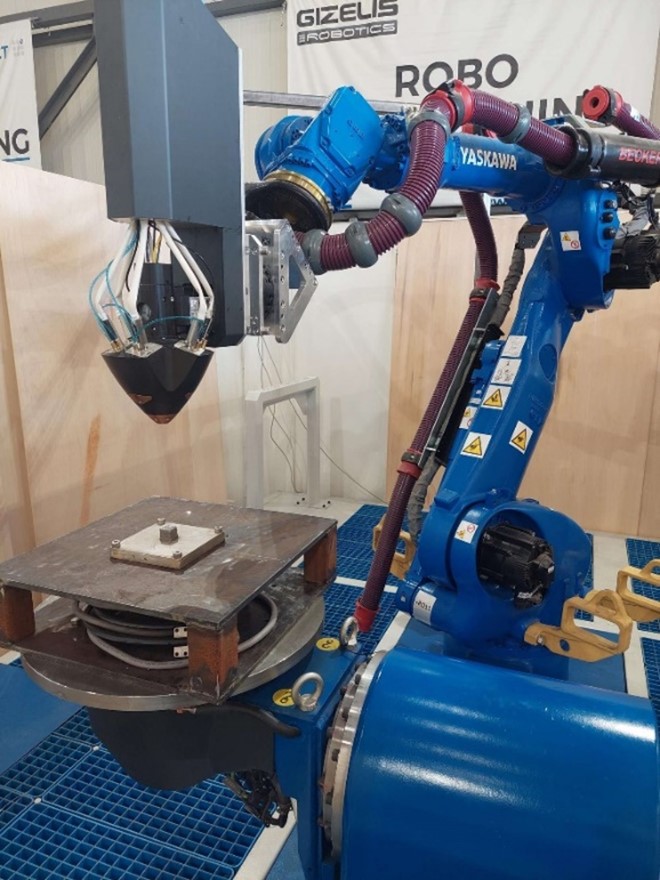

The Meltio Engine has been successfully integrated with the YASKAWA robot and the first experiments regarding the Additive process have been conducted.

Integration of the Meltio Engine with the YASKAWA GP225 robot within the HybridR project has been accomplished on Gizelis Robotics premises, from the HybridR project consortium with ANiMA assistance.

Figure 1: YASKAWA robot and Meltio Engine after the integration

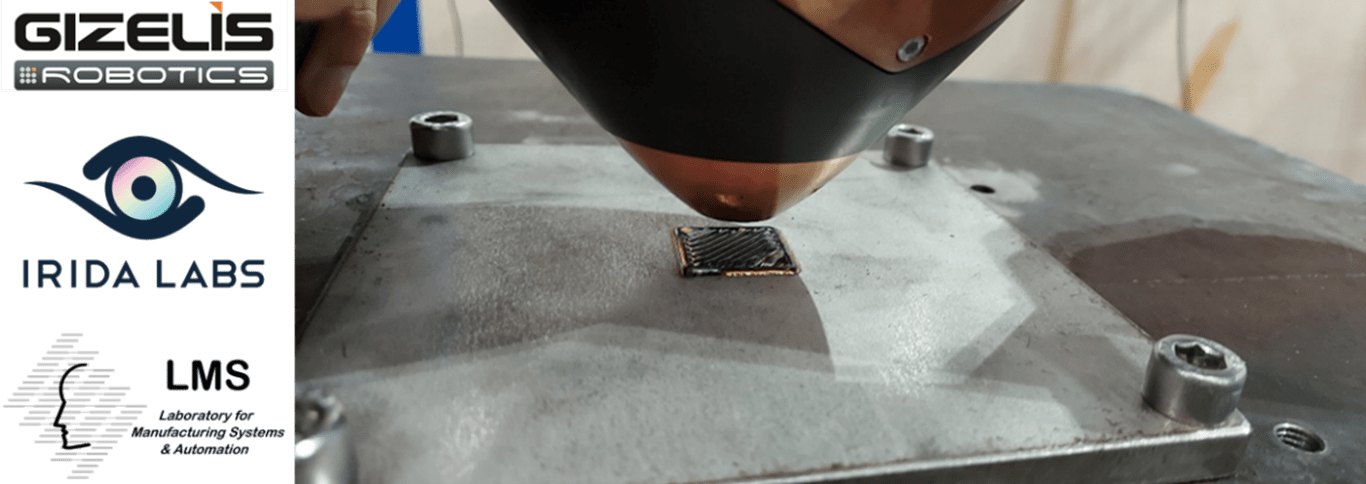

Meltio Engine uses Laser Metal Deposition (LMD), which is a Directed Energy Deposition (DED) process that supports both powder and wire form material printing. Multi Material printing is also feasible, supporting materials such as Stainless Steel, Titanium and Nickel. Robotics based AM enables in-line AM as a sub-process in an existing production flow, allowing us to accomplish multiple manufacturing processes (machining, cladding etc.) and quality inspection systems such as 3D scanners in a single manufacturing cell.

Figure 2: Additive process snapshot

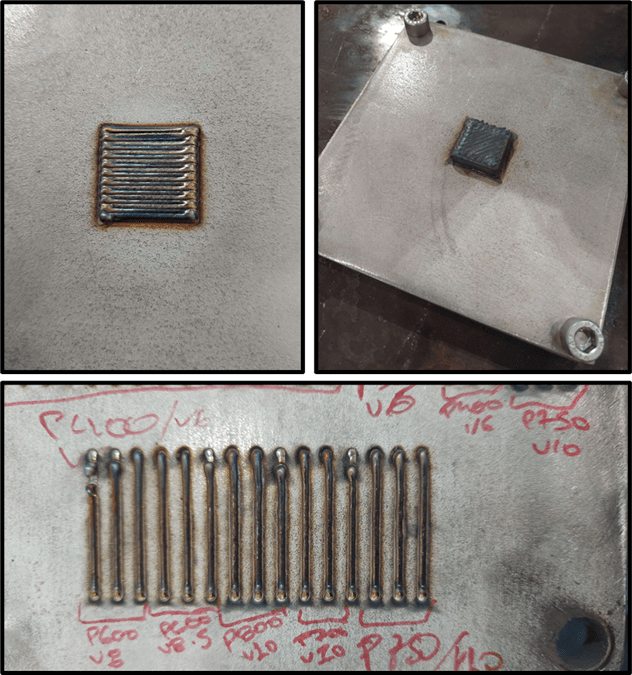

Process development

After the integration was completed, a series of experiments have been conducted from the consortium towards process development for 316 Stainless Steel. Several test coupons have been printed, ranging from single tracks and layers up to simple shapes such as cubes. Different process parameters have been used to understand the system behavior and extract the best process window for this specific material.

Figure 3: Printed test coupons