Blog

Digital Twins for robotic machining

Digital Twins for robotic machining

HybridR consortium provides a solution for accurate process planning of the robot machining process using Digital Twins.

The use of robots for milling operations seems to be a logical step since they offer high flexibility to a manufacturing system and present several major advantages over conventional CNC machines. In specific, milling with robots offers larger working envelopes without increasing the cost, while due to their flexible kinematics they can reach and move in tight areas, to produce parts with complex shape. However, robots have an inherent problem with structural stiffness, as most of them are designed as open, serial kinematic chains supported by rotational joints. Consequently, the cutting forces applied to the tool tip during milling operations can lead to serious trajectory deviations, when high cutting loads are applied, resulting in an accuracy that cannot meet the requirements of several industrial sectors.

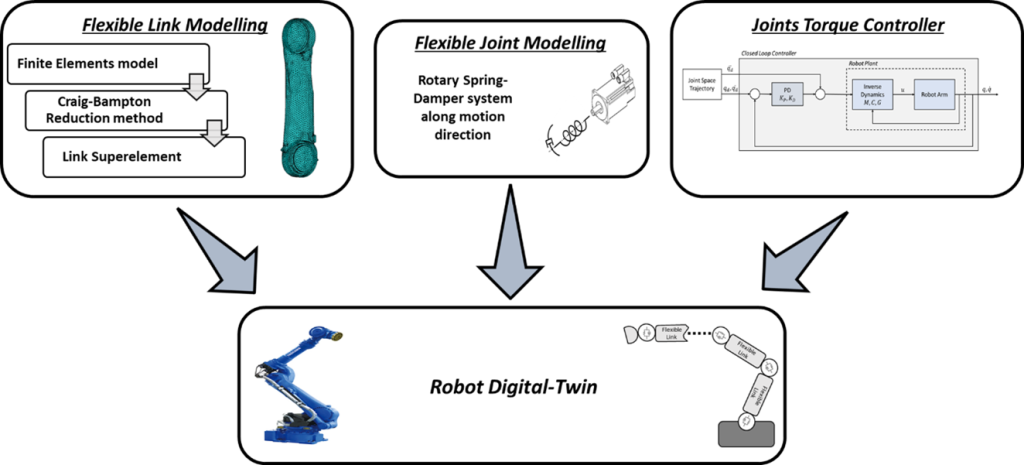

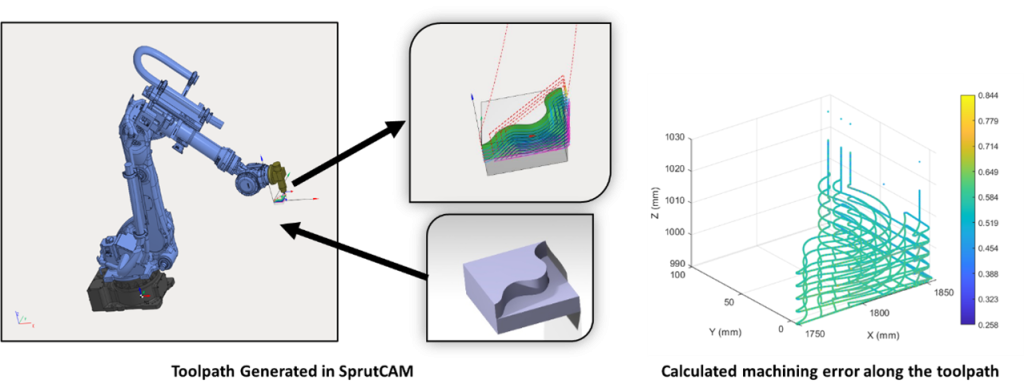

HybridR provides a solution to tackle this issue through advanced simulation and Digital Twins of the robot machining process. A dynamic model of the machining robot of HybridR has been developed, using the Multi-Body Simulation (MBS) and Component Mode Synthesis (CMS) methods, which is able to calculate the robot deflections throughout the toolpath. The simulation is linked with SprutCAM (the CAM s/w used for programming the HybridR cell), in order to adapt the process plan automatically, based on the user requirements in terms of machining tolerances and the simulation results

Through the simulation results, the machining error can be calculated along the whole toolpath length. Additionally, the feed rate of the robot can be automatically adjusted locally, to optimize the process and ensure that tolerances are met throughout the whole part.

More information can be found in the corresponding scientific article that has emerged from this development.

- Stavropoulos, C. Gerontas, H. Bikas, T. Souflas, “Multi-Body dynamic simulation of a machining robot driven by CAM”, 55th CIRP Conference on Manufacturing Systems, Volume 107, pg. 764-769 , 29 June – 1 July, Lugano, Switzerland (2022)